-

03:32

Do you understand what it means? You must have different feelings when you watch this movie!

Do you understand what it means? You must have different feelings when you watch this movie! -

00:44

Beauty Welfare Club 0988: fair-skinned beauty, netizen: can pinch out water

Beauty Welfare Club 0988: fair-skinned beauty, netizen: can pinch out water -

02:24

Happy Halloween Trick-or-treat night indoors places listed pictures

Happy Halloween Trick-or-treat night indoors places listed pictures -

00:22

Preparedness Daily Chinese Style

Preparedness Daily Chinese Style -

00:31

The change of Du Yuesheng is from external image to internal accomplishment.

The change of Du Yuesheng is from external image to internal accomplishment. -

02:12

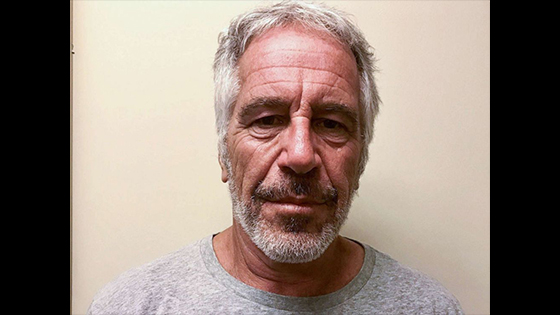

Jeffrey Epstein's death apparent suicide prompts conspiracy theories

Jeffrey Epstein's death apparent suicide prompts conspiracy theories -

00:59

The injured wild boar blocked the hole desperately and was moved when he saw it inside.

The injured wild boar blocked the hole desperately and was moved when he saw it inside. -

00:41

Mona Lisa moved for the first time in 14 years, the original exhibition hall needs to be renovated for 3 months.

Mona Lisa moved for the first time in 14 years, the original exhibition hall needs to be renovated for 3 months. -

01:12

You know what? What are the benefits of a harmonious couple's life for their health?

You know what? What are the benefits of a harmonious couple's life for their health? -

00:55

Why is Mercedes-Benz so expensive? At the moment of the collision, you know why.

Why is Mercedes-Benz so expensive? At the moment of the collision, you know why.

Lightweight and sturdy plastics are everywhere and are relevant to our lives. However, most plastic waste cannot be recycled and will eventually be landfilled or incinerated. According to United Nations statistics, approximately 300 million tons of plastic waste are generated each year worldwide. This kind of garbage, which takes centuries to break down, has even entered the deepest part of the ocean and entered the food chain, which is endangering the health of earth creatures, including humans. The good news is that researchers at Lawrence Berkeley National Laboratory (LBNL) have developed a new type of plastic that can be dismantled and recycled again and again at the molecular level like Lego toys, and then reconstituted into any color, shape or form. Products without loss of performance or quality. Using this new material called poly(diketone acetamide) or PDK, the invariant molecular bonds of traditional plastics are replaced by reversible molecular bonds that can be reduced to their monomeric molecules by breaking their molecular bonds, such as with concentrated acids. Separate the chemical additives before re-assembling as needed to give the plastic a new look and attributes. The researchers then plan to develop PDK plastics with heat resistance and higher mechanical properties for a variety of applications such as textiles, 3D printing and foam. In addition, they hope to expand their formulations by introducing plant materials and other sustainable sources.